To sign up for our daily email newsletter, CLICK HERE

Product packaging plays a pivotal role in the new product innovation process. As the first point of contact between consumers and your product, packaging can make or break the success of your launch.

This article will provide an authoritative guide on the 9 essential steps brands should take to rigorously test their packaging to maximize the chances of marketplace success.

Understanding Packaging’s Role in New Product Innovation

Creating new products is a grueling process. In the ever-evolving landscape of product innovation, the role of packaging stands out as a critical determinant of success. The assertion that packaging significantly shapes consumer choices is underscored by a substantial 72% of consumers who acknowledge its influential role in their purchasing decisions. This places packaging at the forefront of the consumer’s initial interaction with a product, emphasizing its pivotal role in shaping perceptions and driving favorable purchase behaviors.

Packaging goes beyond mere aesthetics; it serves as a visual representation of a product’s quality and functionality. Consumers often infer the quality of a product based on the packaging it comes in. An appealing, well-designed package not only creates a positive first impression but also conveys a commitment to excellence. Moreover, packaging communicates functional attributes, with clear labels and user-friendly features contributing to consumers’ perceptions of a product’s utility. It’s therefore important to have high-quality custom labels from a company such as Columbine Label Company as your product packaging communicates a lot to your customers and therefore should not compromise on quality.

Sustainability has emerged as a key consideration for today’s conscious consumers, and packaging plays a crucial role in reflecting a brand’s commitment to eco-friendly practices. The increasing importance of sustainability is evident in packaging materials that are recyclable, environmentally friendly, and contribute to reduced ecological impact. When packaging aligns with consumers’ values, such as sustainability and social responsibility, it establishes a deeper connection and fosters brand loyalty.

Assembling the Right Team for the Packaging Test

Driving market success for new product innovation is intricately tied to adopting a cross-functional team strategy during packaging testing. Bringing together individuals from various departments ensures a diversity of perspectives and expertise, which is invaluable in identifying and addressing potential issues from different angles.

Representatives from Research and Development (R&D) contribute technical insights, marketers provide an understanding of consumer preferences, graphic designers offer expertise in visual appeal, and manufacturing and sales professionals provide practical considerations for production and market positioning.

Tailoring testing methodologies to the unique attributes of the product and brand is another critical aspect. No one-size-fits-all approach exists for packaging testing, as different products and brands have distinct requirements and goals. The team should collaborate to design testing methodologies that capture relevant data, considering factors such as target demographics, market positioning, and the desired consumer experience. This tailored approach enhances the accuracy and applicability of the insights gained through testing.

Designing an Impactful Packaging Test

The packaging test design should reflect real-world scenarios of how target consumers will interact with your product. Focus groups, surveys, in-store studies, and eye-tracking offer rich insights. Craft tests to evaluate:

- Shelf-standout

- Conveyance of product attributes

- Legibility and Visual Hierarchy

- Sustainability perceptions

- Quality cues

- Brand alignment

Carefully Selecting a Representative Participant Sample

No matter which packaging test methods you choose, the participant sample must reflect your actual consumer demographic and psychographic profiles. Leverage consumer data and work with research agencies to recruit an accurate panel size for statistical significance.

Executing the Test Protocol

Conduct each test scenario in a controlled environment mirroring real-world conditions, utilizing technology like mobile eye-tracking to map subconscious reactions. Refer to testing standards like ASTM F3263 while ensuring flexibility to meet product-specific requirements.

Analyzing the Packaging Test Results

Compile qualitative feedback and quantitative data gathered. Identify trends and correlations around visual attention, touch interactions, and emotional sentiment using heatmap analysis, gaze plots, and more. Convert findings into actionable insights to enhance the packaging design and function.

Iterating the Packaging Design Based on Learnings

Once the initial packaging test analysis is complete, the next step in the optimization process involves making informed updates to various elements of the packaging design. This can include adjustments to the aesthetic, layout, messaging, and even tactile elements such as textures.

The goal is to refine the packaging to better align with consumer preferences, enhance visibility on the shelf, and effectively communicate the product’s value proposition.

Aesthetic updates: This may involve tweaking color schemes, graphic elements, or overall design themes based on feedback and performance indicators from the initial testing phase. Layout adjustments could focus on optimizing the arrangement of product information, images, and branding elements to create a more visually appealing and informative package.

Messaging: This is a critical aspect of packaging and should resonate with the target audience. Emphasizing quality cues that align with consumer values can create a stronger connection between the product and its intended market. For instance, if sustainability is a key value for consumers, messaging that highlights eco-friendly practices or materials can be incorporated into the packaging design.

Textures and tactile elements: This contributes to the overall sensory experience of interacting with the product. Evaluating how different textures are perceived by consumers during the testing phase can inform decisions on whether to maintain or modify these elements for better engagement.

Before finalizing these updates, it’s prudent to conduct further small-scale tests. This allows for a more focused evaluation of the proposed iterations to ensure they resonate as intended with the target audience. Small-scale tests can provide additional insights and catch any potential issues before a broader rollout.

Sustainability in Packaging: Creating Cost-Effective Solutions

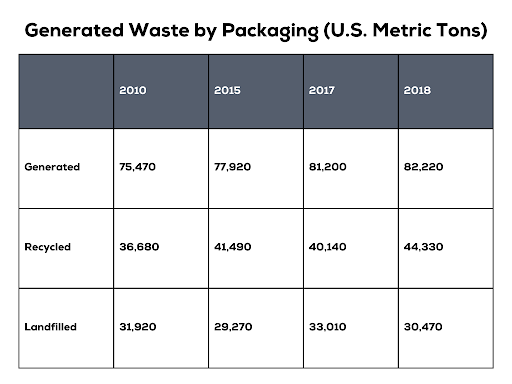

Source: Environmental Protection Agency

Incorporating sustainability into the packaging iteration process is integral for businesses committed to environmental responsibility. From the choice of materials to the overall design, a sustainable approach involves using recycled or biodegradable materials to minimize the ecological footprint. Reducing packaging waste is a key objective, and this can be achieved by adopting minimalist designs, optimizing packaging size, and eliminating unnecessary elements.

Furthermore, clear communication of the product’s sustainable attributes on the packaging itself is crucial. Consumers increasingly prioritize eco-friendly practices, and transparent messaging builds trust.

Finalizing an Impactful Packaging Design

Integrate effective and authentic brand messaging into aesthetically striking visuals optimized for shelf differentiation and hierarchy of information. Confirm the design effectively communicates product sustainability practices and elicits your desired brand image through a final validation test.

Post-Launch: Continuously Optimizing Packaging

Optimizing packaging doesn’t end with the product launch; it’s an ongoing process that requires careful monitoring and adaptation.

Treat packaging as a living asset. Track sales velocity, consumer feedback, and market trends post-launch to identify areas for continued optimization. Dig deeper into the new product innovation process to ensure your packaging evolves in step with consumer needs and technological advances.

Consumer tastes may evolve, or technological advancements could present new possibilities for packaging innovation. By staying informed and adapting to changes in the external environment, packaging can evolve in tandem with emerging trends and consumer preferences.

Frequently Asked Questions

What is the importance of packaging testing for new product innovation?

Rigorous packaging testing is crucial in the new product innovation process, spurring refinement that helps products resonate at market launch. One study found that 30% of businesses see a revenue increase after improving packaging.

What are some packaging test methodologies?

Methodologies include focus groups, shopper observation, eye tracking studies, shelf/lab tests, and stress testing. Each provides unique insights to optimize technical function and aesthetic appeal from consumer perspectives.

Should you finalize the packaging before launch?

While locking down design is important pre-launch, brands should continuously test and refine packaging post-launch as consumer data and technological capabilities evolve, keeping packaging fresh and relevant.

Effective, authentic packaging is imperative for new products to rise above the competition. By investing in consumer-driven testing and a culture of iteration, brands can unlock lasting marketplace success.