To sign up for our daily email newsletter, CLICK HERE

The world of CNC Machines is all about Precision and innovation. The industry revolutionized manufacturing and enabled you to create complex components from raw materials. Whether you’re a curious mind seeking knowledge or simply fascinated by the world around you, learning about CNC machining is a must. It’s a gateway to understanding the complex processes behind the everyday objects we take for granted, and it’s a testament to human creativity and the power of technology.

For your learning, this article delves into the versatility of CNC machining by exploring the types of CNC machines available in Machine shop. The techniques will also provide you with deep insights into why they are needed in the Machine shop in first place.

Let’s start with Types.

Types of CNC Machines in Machine Shops

CNC machines have become crucial in modern manufacturing, offering a wide range of space and capabilities for creating complex and precise parts. In a typical machine shop, you’ll find a variety of CNC machines, each with unique strengths and applications.

Figure: Different Types of CNC Machining

CNC Lathes: The Versatile Workhorses of Manufacturing

CNC lathes are among the most versatile machines capable of producing various cylindrical and rotational parts. They rotate the workpiece while a cutting tool is fed against it to remove material. CNC lathes are commonly used to make parts such as shafts, gears, and spindles. Their versatility originates from their ability to perform various machining operations, including turning, facing, drilling, boring, and grooving.

Components of a CNC Lathe

A typical CNC lathe consists of the following major components:

- Bed: The bed forms the foundation of the lathe and provides a stable platform for the other members.

- Headstock: The headstock houses the main spindle, which rotates the workpiece. The spindle speed is controlled by a servo motor or a variable frequency drive (VFD).

- Carriage: The carriage travels along the bed and carries the cutting tool. A servo motor or a stepper motor controls it.

- Cross Slide: The cross slide moves perpendicular to the carriage and controls the depth of the cut. A servo motor or a stepper motor also controls it.

- Tailstock: The tailstock supports the workpiece on the non-rotating end. It is adjustable to adjust workpieces of different lengths.

- Control System: The control system is the brain of the CNC lathe. It analyses the programmed instructions and commands the various components to perform the selected machining operations.

Machining Operations on a CNC Lathe

CNC lathes can perform a variety of machining operations, including:

- Turning: Turning is the primary operation of a lathe and involves removing material from the rotating workpiece to create a cylindrical shape.

- Facing: Facing involves removing material from the end of the workpiece to create a flat surface.

- Drilling: Drilling consists of making holes in the workpiece.

- Boring: Boring involves enlarging existing holes in the workpiece.

- Grooving: Grooving consists of cutting a groove or channel into the surface of the workpiece.

Applications of CNC Lathes

CNC lathes are used in many industries, including:

- Automotive: CNC lathes produce various automotive parts, such as shafts, gears, and spindles.

- Aerospace: CNC lathes produce precision aerospace components, such as engine parts, landing gear components, and structural components.

- Medical: CNC lathes produce medical devices, such as implants, prosthetics, and surgical instruments.

- Tool and Die Making: CNC lathes produce precision tools and dies for various manufacturing processes.

- General Manufacturing: CNC lathes are used in various general manufacturing applications, such as producing parts for machinery, appliances, and consumer goods.

CNC lathes are powerful machines that are necessary for modern manufacturing. They can produce a wide range of precision parts effectively. As technology advances, CNC lathes are becoming even more sophisticated.

CNC Mills: Masters of Milling and Shaping

CNC mills are another versatile type of CNC machine that can

produce many shapes and features. They move a cutting tool along three or more axes to remove material from a workpiece. CNC mills commonly make parts such as moulds, dies, and housings.

Anatomy of a CNC Mill

A typical CNC mill comprises several key components that work together to complete complex machining operations:

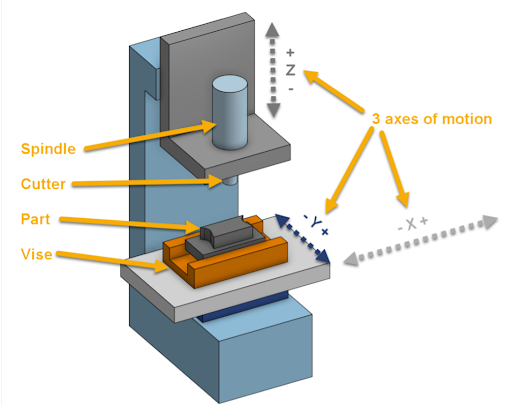

Figure: Anatomy of a CNC Machine

- Base: The base provides a solid foundation for the entire machine, providing stability and vibration dampening during operation.

- Column: The column, also known as the upright, serves as the vertical support for the spindle head and cross slide. It houses the Z-axis drive mechanism, making vertical movement.

- Spindle Head: The spindle head, mounted atop the column, houses the spindle, which rotates the cutting tool at high speeds. A servo motor or a variable frequency drive controls the spindle speed.

- Saddle: The saddle, attached to the column, carries the cross slide and travels along the longitudinal axis (X-axis).

- Cross Slide: The cross slide moves perpendicular to the saddle and carries the tool ram, allowing for lateral movement (Y-axis).

- Tool Ram: The tool ram holds the cutting tool and is responsible for tool insertion, retraction, and depth of cut control.

- Table: The table, mounted on the base, supports the workpiece and can move in two axes (X and Y) to position it precisely under the cutting tool.

- Control System: The control system, the brain of the CNC mill, interprets programmed instructions and commands the various components to execute the desired machining operations.

Machining Operations on a CNC Mill

CNC mills perform a diverse range of machining operations, including:

- Milling: Milling involves removing material from the workpiece using a rotating cutting tool. It is the primary operation of a CNC mill.

- Facing: Facing involves removing material from a flat surface of the workpiece to create a smooth, level plane.

- Drilling involves creating holes of various sizes and depths in the workpiece.

- Boring: Boring involves enlarging existing holes in the workpiece to precise dimensions.

- Slotting: Slotting involves creating grooves or rectangular pockets in the workpiece.

- Contour Milling: Contour milling involves following a predefined path to create complex shapes and contours on the workpiece.

Applications of CNC Mills

CNC mills are necessary tools in various manufacturing industries, including:

- Aerospace: CNC mills are crucial in crafting precision aerospace components, such as engine parts, structural components, and landing gear parts.

- Automotive: CNC mills produce various automotive parts, including moulds for engine blocks, dies for stamping body panels, and intricate gears.

- Tool and Die Making: CNC mills are essential for producing precision tools and dies used in manufacturing, such as stamping, forging, and casting.

- Moldmaking: CNC mills are employed to create moulds for various applications, including plastic injection moulding, die casting, and glass moulding.

- General Manufacturing: CNC mills are widely used to produce many parts, such as housings, brackets, and components for machinery, appliances, and consumer goods.

CNC mills are the backbone of modern manufacturing, allowing the creation of complex and precise components that drive innovation and technological advancement. .

CNC Routers: Masters of Carving and Shaping

CNC routers are specifically designed for cutting and shaping wood, plastics, and other soft materials. They use various cutting tools like bits and end mills to create intricate designs and patterns. CNC routers make furniture, signs, and other decorative items.

Anatomy of a CNC Router

A typical CNC router consists of several key components that work in unison to execute complex machining operations:

- Frame: The frame provides a rigid and stable foundation for the machine, ensuring stability and vibration dampening during operation.

- Gantry: The gantry, or the overhead unit, travels along the longitudinal axis (X-axis) and houses the spindle and tool carriage.

- Z-Axis Column: The Z-axis column, mounted on the frame, provides vertical support for the gantry and enables vertical movement (Z-axis).

- Spindle: The spindle, mounted on the gantry, rotates the cutting tool at high speeds. The spindle speed is controlled by a servo motor or a variable frequency drive (VFD).

- Tool Carriage: The tool carriage, attached to the gantry, carries the cutting tool and moves along the lateral axis (Y-axis).

- Table: The table, mounted on the frame, supports the workpiece and can be moved along two axes (X and Y) to position it precisely under the cutting tool.

- Control System: The control system, the brain of the CNC router, interprets programmed instructions and commands the various components to execute the desired machining operations.

Machining Operations on a CNC Router

CNC routers are capable of performing a wide range of machining operations, including:

- Routing: Routing involves removing material from the workpiece using cutting tools like bits and end mills. It is the primary operation of a CNC router.

- Profiling involves following a predefined path to create complex shapes and contours on the workpiece.

- Pocketing: Pocketing involves removing material from a defined area within the workpiece, creating pockets or recesses.

- Slotting: Slotting involves creating grooves or rectangular pockets in the workpiece.

- Engraving: Engraving involves etching or carving designs or text onto the workpiece.

Applications of CNC Routers

CNC routers find widespread application in various industries, including:

- Sign making: CNC routers are required in the signmaking industry, allowing the creation of custom signs, logos, and displays.

- Prototyping: CNC routers often create physical models of new designs and products.

CNC Plasma Cutters: The Versatile Machine for Cutting Various Materials

CNC plasma cutters use a powerful stream of ionized gas to cut through various materials, including metals, plastics, and composites. They are particularly well-suited for cutting thick materials and making large parts. CNC plasma cutters are used in the automotive, aerospace, and construction industries

Anatomy

A CNC plasma cutter consists of the following components:

- Power supply: The power supply is needed for electrical power necessary to ionize the gas used for plasma cutting.

- Torch: The torch holds the cutting electrode and directs the plasma stream towards the workpiece.

- CNC controller: The CNC controller controls the movement of the torch and the cutting process.

- Workpiece table: The table supports the workpiece and can be moved to accurately position it under the torch.

Applications

CNC plasma cutters are used to cut material such as metals, plastics, and composites. They are used in the following applications:

- Automotive: Cutting car bodies, frames, and other components

- Aerospace: Cutting aircraft parts, such as wings, fuselage panels, and engine parts

- Construction: Cutting steel beams, pipes, and other structural components

- Signmaking: Cutting signs, logos, and other decorative pieces

- Metal fabrication: Cutting metal parts for a wide variety of applications

CNC Laser Cutters: Unleashing the Power of Light for Intricate Cuts

CNC laser cutters use a high-powered laser beam to cut through various materials, including metals, plastics, and wood. They are capable of producing exact and intricate cuts. CNC laser cutters are commonly used in the electronics, medical device, and jewelry industries.

Components

- Laser: The laser generates a high-power beam of light to cut the workpiece.

- Optics: The optics are to focus the laser beam onto the workpiece and control the size and shape of the cut.

- CNC controller: The CNC controller controls the laser movement and the cutting process.

- Workpiece table: The table supports the workpiece and can be moved to accurately position it under the laser.

Applications

CNC laser cutters are used to cut various materials, such as metals, plastics, and wood. They are commonly used in the following applications:

- Electronics: Cutting circuit boards, electronic components, and other sensitive materials

- Medical: Cutting stents, implants, and other medical devices

- Aerospace: Cutting aircraft parts, such as wings, fuselage panels, and engine parts

- Automotive: Cutting car bodies, frames, and other components

- Consumer goods: Cutting appliances, toys, and other consumer products

CNC Electrical Discharge Machines (EDMs): Mastering the Art of Machining Hard Materials

CNC EDM uses electrical sparks to remove material from a workpiece. They are particularly well-suited for cutting hard and brittle materials, such as carbide and hardened steel. CNC EDMs are commonly used to make molds, dies, and other precision components.

Anatomy

A CNC EDM consists of the following components:

- Electrode: The electrode is the tool that removes material from the workpiece.

- Dielectric fluid: The dielectric fluid surrounds the electrode and the workpiece and helps to remove debris and disperse heat.

- CNC controller: The CNC controller controls the movement of the electrode and the machining process.

- Workpiece table: The workpiece table supports the workpiece and can be moved to position it accurately under the electrode.

Applications

CNC EDMs are used to cut hard materials and are challenging for other machines. They are commonly used in the following applications:

- Tool and die making: Cutting dies, molds, and other precision tools

- Medical: Cutting surgical instruments, implants, and other medical devices

- Aerospace: Cutting aircraft parts, such as engine components, fuel injectors, and landing gear parts

- Electronics: Cutting circuit boards and other electronic components

- General machining: Cutting a wide variety of hard and brittle materials.

The other such machines that are crucial part of Machine shop are CNC Grinding Machines, CNC Drilling Machines and CNC Waterjet Cutting Machines.

CNC Machines: The Superheroes of Modern Machine Shops

Machine shops are hubs of creativity and metalworking magic. Just like superheroes have their trusty assistants; machine shops rely on the incredible powers of CNC machines to beat the challenges of modern manufacturing.

Precision

Traditional manual machines might be strong, but they can’t match the precision and accuracy of CNC machines.

Productivity

CNC machines are the real speedsters of manufacturing. They can operate continuously.

Versatility

CNC machines are the chameleons of the machine shop world, capable of handling a wide range of materials, from metals and plastics to composites and wood.

Safety

CNC machines are the safety guardians of the machine shop, minimizing the risk of accidents and injuries.

Figure: Machine Shop showcasing variety of CNC Machines

Future-Proof Technology

CNC machines aren’t just the tools of today; they’re the building blocks of the future. With artificial intelligence, cutting-edge tech and machine learning joining the party, CNC machines are becoming even more efficient and ready to take manufacturing to new heights.

In conclusion, CNC machines are not merely tools; they are a force for innovation and efficiency in modern machine shops. That is why you will find all the above types of CNC machining in machine shops because, without them, they cannot simply compete and function in the manufacturing industry. CNC machining remarkable precision, enhanced productivity, versatility, and adaptability have revolutionized manufacturing processes, making machine shops produce high-quality components at reduced costs.