To sign up for our daily email newsletter, CLICK HERE

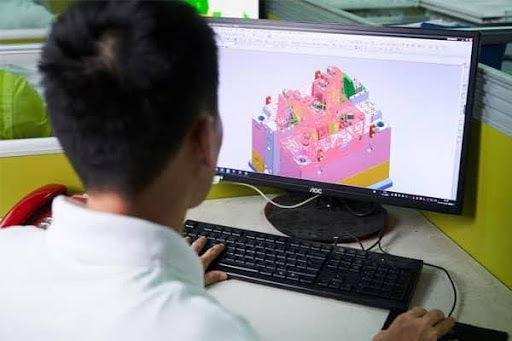

Effective Workflow in Mold Design

Effective plastic injection mold design is of utmost importance, as ensuring a seamless workflow can have a profound effect on both time and resources spent getting products out to market.

An efficient workflow ensures that each step in the design process flows efficiently from one stage to the next, eliminating delays and increasing productivity. By optimizing your mold design process, you can reduce lead times, costs and ensure high quality standards are upheld.

Without an effective workflow, designers may encounter bottlenecks that delay progress, leading to missed deadlines that jeopardise not only timelines, but also project success.

By prioritizing efficiency in your mold design workflow, you can stay ahead of competition and more effectively meet customers’ needs. Optimizing will lead to better results on projects undertaken.

Common Challenges in Traditional Mold Design

Traditional mold design processes often face hurdles that impede efficiency and productivity, including an over-reliance on manual calculations and measurements which often leads to human mistakes and inconsistencies in final products.

Communication gaps among various teams involved in the design process may lead to misunderstands and delays; without an easily accessible platform for collaboration, sharing updates and receiving feedback becomes cumbersome and time consuming.

Traditional methods lack real-time simulation capabilities, making it hard to anticipate potential issues before production begins and potentially leading to costly mistakes that could have been prevented using more modern software solutions.

Managing revisions and iterations manually is time consuming and subject to oversight; without version control features in place, tracking changes becomes an arduous task for designers working on complex projects.

Software Solutions Can Simplify the Process

Time is of the utmost importance in plastic injection molding project, where traditional manual processes may prove both time-consuming and error-prone. Software solutions provide a quick and streamlined method for designing molds efficiently.

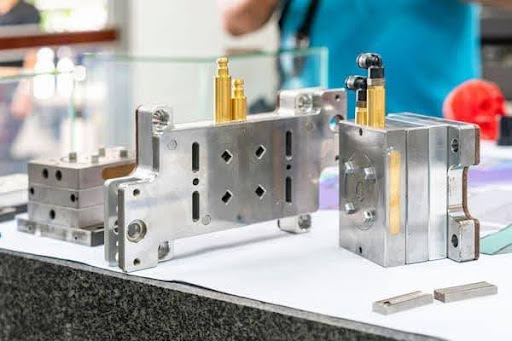

By employing advanced software specifically tailored for mold design, engineers can automate tasks like geometry creation, cooling channel layout and mold base selection – not only saving them valuable time but also guaranteeing accuracy during their design processes. These tools not only save them valuable time but ensure precision during this crucial part of manufacturing.

Software solutions enable collaboration among team members regardless of physical proximity. Real-time updates and cloud storage make it simple for multiple stakeholders to seamlessly contribute their time, skills, and contributions toward projects simultaneously.

As these digital tools offer simulation capabilities that enable engineers to predict potential issues before manufacturing begins, this proactive approach reduces costly mistakes while optimizing overall workflow.

Integrating software solutions into your mold design process can significantly boost efficiency and productivity while simultaneously guaranteeing high-quality results on time.

Key Features to Look Out For in Mold Design Software

Consider these key features when choosing mold design software: they will have an immense effect on your workflow. Look for software with advanced 3D modeling capabilities for precise designs and simulations; this enables you to visualize the end product before production begins.

Integrity of industry-standard file formats is paramount to efficient collaboration between team members and suppliers, and integration with tools like CAD software can further streamline design by eliminating manual data transference processes.

An intuitive user interface is vital to ease of use and faster learning curves. Search for software with customizable templates and libraries that speed common tasks up while decreasing repetitive work.

Additionally, robust analysis tools like mold flow simulation can assist designers in optimizing designs to be both cost-efficient and time efficient. Real-time feedback of potential issues during prototyping or testing phases saves both time and resources.

Selecting mold design software with these key features can greatly enhance productivity, accuracy and innovation within your workflow.

Case Studies of Success of Companies Implementing Software Solutions

Imagine a world in which companies are revolutionizing the plastic injection mold design process through advanced software solutions, like one major manufacturer who significantly decreased design cycle time by adopting dedicated mold design software.

One company saw dramatic improvements in collaboration between their design and engineering teams by adding 3D visualization tools into their workflow, leading to decreased errors, faster iterations time frames and cost savings as a result.

One small business struggling with manual processes found relief through automation features in their chosen software. By automating repetitive tasks, they were freed up to focus on innovation and problem-solving rather than mundane work.

These case studies highlight the real-life implications of adopting technology into mold design. Companies that adopt cutting-edge software solutions gain an edge in an ever-evolving industry.

Implement Software into Your Workflow Solutions

Optimizing your workflow with software solutions for plastic injection mold design can dramatically increase efficiency and productivity, helping companies overcome traditional hurdles while producing greater results in shorter timespan.

Before choosing software to implement in your workflow, it’s essential that you research key features tailored specifically to meet your unique requirements. Look out for functions such as advanced modeling capabilities, simulation tools and seamless integration between systems for an effortless transition process.

Case studies of successful companies showcase the tangible advantages of adopting software solutions for mold design. This serves as inspiration to anyone aiming to streamline processes and remain ahead of competition.

Adopting software into your mold design workflow is more than a trend; it’s about optimizing efficiency, cutting costs, and speeding delivery of superior products faster. Take the plunge towards digital transformation today to transform how you approach plastic injection mold design!