To sign up for our daily email newsletter, CLICK HERE

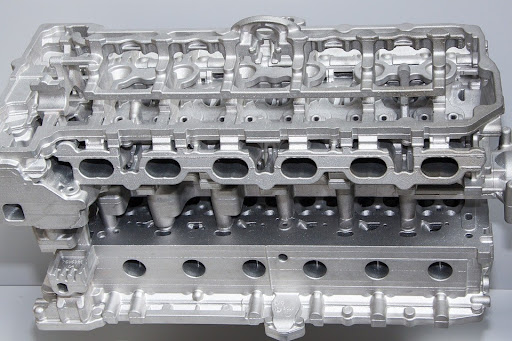

A well cold chamber die casting is characterized by low fluidity and a high degree of plasticity. The metal alloy can be cast into complex components that could not be formed quickly using other manufacturing technologies.

1) Low to nil machining requirements

Unlike sand or permanent mold processes, no machining is required after the casting process for turning, milling, threading, etc. The parts are ready for assembly.

Parts produced through the cold chamber molding process need only a minimal amount of post finishing before being put to use. This means a significant increase in productivity as there will be less time dedicated to additional steps like grinding, polishing, drilling holes, etc.

2) Improved dimensional accuracy

The most significant advantage of die casting is the ease with which close tolerances can be held. A cold chamber die allows for better surface finishes because it does not require finishing operations like machining or polishing between each part ejection.

3) Improved dimensional stability

A significant advantage of cold chamber die casting is its dimensional stability during the process. Because the metal alloys are heated to just below their melting point, there will be no thermal stresses during the cycle resulting in minimal shrinkage. This means that parts will maintain close tolerances throughout the whole process, which also helps eliminate warpage defects.

4) Shorter Cycle Times

The fluidity of metal alloy used in Cold Chamber Die Casting offers considerable savings over permanent mold processes (sand). The short time and hence the shorter cycle means a significant increase in productivity.

5) Improved surface finish

Because there is no sand, there will be no parting lines or material build-up between each cycle like other conventional processes such as sand or permanent casting. This results in perfect surfaces with excellent appearance and an even distribution of porosity throughout the part to enhance fatigue strength.

6) Higher production rates

This is simply because cold chamber die casting machines can be designed to have a high production capability making them ideal for mass manufacturing.

Cold chamber die-cast components are used in various industries, including aerospace, automotive, electrical, electronic products, etc. For those who do not have the necessary skills for this technology, you should know that manufacturers who offer this service are available in the market.

7) Directly cast metals

There are no expendable materials or production steps involved in the Cold Chamber Die Casting process, so it is considered a directly cast technology. This means other than metal alloys and dies casting equipment, and there should be little else required to get the job done. For more about cold chamber die casting click this site, https://www.ekoindustries.com/precision-die-casting/cold-chamber-die-casting/.

8) Highly versatile range of alloy options

There is a wide variety of different metal alloys that can be used for cold chamber die casting. Its success depends on finding one that exhibits low fluidity and high plasticity while still offering excellent mechanical properties such as tensile strength, corrosion resistance, etc.

9) Rework ability

Reworking processes like brazing, welding, grinding, reaming, etc… when required, would not cause dimensional or surface defects in a cold chamber die cast component. This is because the metal alloy used during the process has low fluidity and high plasticity, making it easy to fabricate.

Cold chamber die casting comes from a combination of standard hot-chamber die casting with a secondary injection system that provides cooling with chilled water or ice. Compared with standard hot-chamber dies where molten metal is injected into the mold through a side port, cold chamber dies have one centrally located nozzle, allowing for an equal flow distribution around the entire circumference of the molding cavity.