To sign up for our daily email newsletter, CLICK HERE

As an eCommerce retailer, you fully understand the importance of providing your customers with the best possible products at the lowest possible price. It’s your bread and butter, and your success rises and falls around being able to beat your biggest competitors in both quality and price point.

But you can’t sell products at a loss. When you set your pricing, you must ensure that you’re still making a profit on the items you sell. Otherwise you’re not going to find yourself in business for very long. This shouldn’t be news to you, but you might not know how to get your prices low enough to be competitive with some of your stiffest competition.

After all, manufacturing, shipping, and payroll all take a major financial toll that must be made back before you can experience even a single cent of profit.

It’s possible to help control and reduce your eCommerce costs by streamlining your supply chain processes. But you really need to know the supply chain inside and out to determine where you can improve and cut away dead weight.

In this article, we’re going to walk you through eight steps you can take to control costs through adjustments to the supply chain management process.

How can streamlining your supply chain help you reduce costs?

When we say supply chain management, we mean everything involved with creating and implementing the supply chains that get your products from manufacturers to the distributors, retailers, and, finally, your customers. Every step of this process has costs associated with them, and those costs add up to influence your pricing and your profit margin.

By cutting some of the costs associated with these processes, you’ll be able to dial back your retail price and provide killer savings to your audience.

That means taking a long hard look at everything involved in the supply chain process, like:

- Manufacturing

- Shipping

- Marketing

- Product development

- And much more

There are many moving parts to a company’s supply chain management, and each company is unique. That’s why we’re going to go through several ways you can start looking at your internal processes, and decide where things can be tightened up for the sake of your future profits.

8 ways to streamline your eCommerce supply chain

1. Audit all supply chain processes

The first step to getting to where you need to go is figuring out where you already are. If you’ve been in business for some time, you likely already have your supply chain management procedures laid out.

As we start on our quest to pair down services and save money, we must first make a detailed list of everything you’re currently doing. That means laying out the entire supply chain process from the moment product development begins to the moment the customer holds the product in their hands for the first time.

This should be a detailed list, illustrating how long each step takes, who works on it, who your third-party partners are, and how much each step in the process costs. Once you have all of this in front of you like a roadmap, you can go through every step again and figure out where there’s room for optimization.

2. Look into factory-direct manufacturing

The manufacturing process is one of the first things you should consider after your audit. If you’re not connecting directly with the factory itself, then you’re throwing money out the door.

This open communication with the production team can help you set goals and expectations around key manufacturing elements like:

- Turnaround time

- Shipments

- Manpower

- Production costs

When the factory understands what you’re looking for, the team can streamline your production. This will bring your products to market faster. Factory-direct manufacturing partners are great at this because there’s no intermediary facilitating communication and shipping between the manufacturers and your online store’s warehouse or storage facility.

3. Examine all sourcing options – Be open to a change

If you find that such direct communication with the members of your manufacturing team isn’t helping to control costs, it might be time to look at other options. When searching for a sourcing partner, you typically want someone who can produce high-qualityproducts while keeping costs down and turn around times quick.

If your current source cannot meet your expectations, you need to be flexible enough to know when it’s time to look elsewhere.

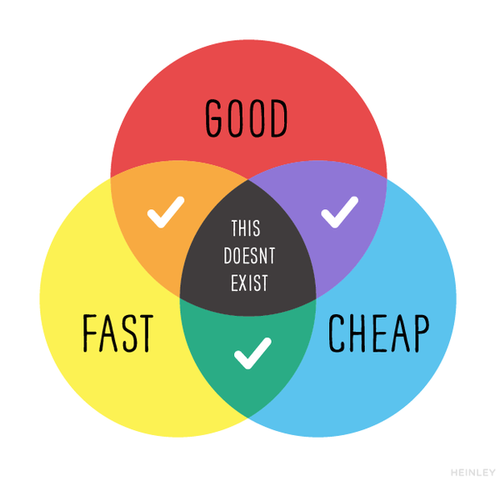

Of course, it’s hard to find a fast, affordable, and high-quality provider. Usually, you need to decide which two out of these three are most important to you and go with someone who can meet you most of the way.

Consider all possibilities, including potential sourcing partners both domestically and abroad. If you feel like a change is needed, discuss it with your internal team and see if they agree. If your current source cannot provide you with what you need, you owe it to yourself and the future success of your eCommerce store to go with someone who will.

4. Tighten up communication inside and outside the company

We touched briefly about establishing streamlined communication with your manufacturer, but that’s also something that should be implemented company-wide through all segments of your supply chain.

Communication is what powers productivity. If teams are communicating back and forth with one another, everyone knows what everyone is doing and when they can expect to take over with their role in the supply chain.

This includes marketers, salespeople, managers, web designers, and even warehouse personnel, security professionals, and delivery drivers, all of whom have an important role to play.

The efficiency that is bred by communication also creates enhanced safety. Warehouse personnel, security, and fleet courier solutions are crucial parts of your supply chain. They will have an open forum to communicate about the safety equipment and logistics they need to properly do their jobs and improve turnaround time.

Provide your fleet with dash cams, GPS tracking, and ELDs to keep driver operations hassle-free and ensure your warehouse has available site visibility solutions.

5. Reduce shipping costs and turn-around time

Shipping can be a huge profit sucker, driving up the cost of your products and making you far less appealing to members of your target audience. That’s why, much like we mentioned earlier, with your sourcing partners, you should always be looking for new, affordable, reliable, and fast shipping partners who can help chop some time and money out of your supply chain.

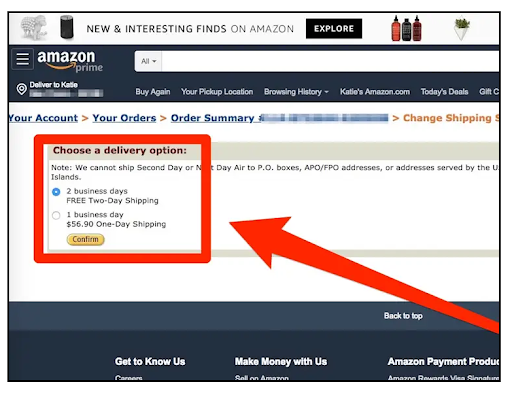

As an eCommerce platform, your single biggest competitor will always be Amazon. They’re the undisputed king of the eCommerce world, offering free shipping to prime members with the ability to ship to most homes in the US in just one day.

That’s not easy to compete with, so you always need to be on the lookout for expedited affordable shipping. Never rest on your laurels, even after signing on with a shipping partner. You should regularly check the market, shopping around the see if a better and more affordable alternative exists.

6. Cut out redundant tasks

After your audit, you should look at your internal processes, including sales, marketing, quality assessment, warehouse, and more. The employees in these vital roles only have a set amount of time on their hands. That time is precious and expensive and should be maximized.

Take a look at the daily tasks for each team member. Is there any wasted time? Are there duplicate or redundant tasks that are being prioritized over other more vital functions? When considering the tasks that make up the day of a supply chain team member, consider implementing the Eisenhower Matrix.

This time prioritization strategy developed by US president Dwight D. Eisenhower was designed to separate all tasks into four different categories.

- The most important and time-sensitive tasks were filed under “Do.”

- Important tasks that didn’t have an impending deadline were filed under “Schedule.”

- Anything unimportant that still needed to get done was put into a section called “Delegate.”

- Finally, unimportant or redundant tasks were filed under “Delete.”

7. Invest in automation

A powerful automation platform could help revolutionize your supply chain management, taking small, inconsequential, and mindless tasks and having a computer system automatically complete them at the speed of light whenever certain criteria are triggered.

For example, when someone places an order on your website, the automation platform can pick up on this and forward the order to the warehouse and your shipping partners to ensure that it’s ready to go out as fast as possible. Compare that to an unenthusiastic human employee who receives the order but forgets to send it along until several hours later.

Remember, your supply chain suffers when orders are backlogged, or warehouse shelves run low on products because someone forgot to order more stock. Thankfully, these automation platforms are available 24/7 to assist your staff, ensuring that everything is done the right way right away.

8. Use task management platforms

A disorganized team will make preventable errors that can set back your supply chain management processes and throw your entire store’s profitability out of whack.

That’s why having everyone scheduled out on a task management platform is important. This allows your team members to see exactly what they need to do, when they need to do it, and document that it was done.

The next person that has to interact with this order can see everything completed up to that point. Not only does this help keep your staff productive, but it also holds them accountable for their tasks.

You have a paper trail showing who did what and when. The team members can even leave notes on each task with any important information that would be needed further down the supply chain. To streamline communication, you can equip your team with an email management tool like Superhuman and an instant messaging app like Slack.

Conclusion

Your supply chain has a direct impact on the prices that customers see when they log onto your online store. By ensuring that your supply chain is managed properly, you can keep costs down and create a more profitable enterprise that can continue to scale into the future.

To review, make sure that you:

- Audit your supply chain processes to figure out where you’re starting from

- Look into factory-direct manufacturing and communicate with your manufacturing partners

- Don’t be afraid to look for new sourcing options

- Tighten up communications and safety company-wide

- Reduce shipping costs and turnaround time to compete with big retailers like Amazon

- Cut out redundant tasks

- Invest in an automation platform

- Have your team use task management software

By adhering to these eight steps, you’ll be able to create a tight and efficient supply chain that will allow you to offer your products at a fair price that’s competitive with your biggest rivals.

About The Author

Sarang is a passionate Content marketer and Account Manager at uSERP. He loves creating content and runs a blog on filmmaking and advertising.